Automatic Panel Nailing, Calibration and Palletizing

Project task

To design an automatic panel nailing, gauge calibration and palletizing machine. Reducing the number of people required on a production line.

Previous working

The panels were nailed, calibrated and loaded onto the pallet by hands. A lot of physical force is used, the workplace is not ergonomic and the production efficiency is low.

Result

The semi-automatic panel production line has been designed and manufactured.

The line consists of pallet forging equipment and a robotic panel calibration and palletizing unit.

It only takes three people to service the whole line.

Physical work is eliminated, safety during the process is ensured and production efficiency is increased

”

Testimonial

When choosing the right business partner, the proposed solutions and examples of fulfilled projects are very important to us. We are glad to have chosen UAB "Automatikos Biuras" because after listening to our needs, they quickly analyzed the technical task. At each stage of the project, the work was carried out smoothly, following the agreed commitments. The company not only fully implemented the requirements but also offered new solutions for future projects. We are very satisfied with the overall result of the work and highly appreciate the work experience as well as the competence of the members of UAB Automatikos Biuras.

- Main automation products

-

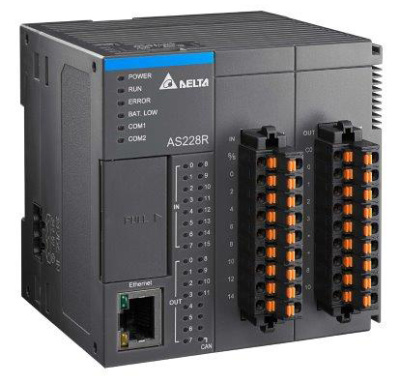

Programmable Logic Controller AS228P-A

Programmable Logic Controller AS228P-A -

Touch Panel DOP-110WS

Touch Panel DOP-110WS -

Frequency Inverter VFD022E21A

Frequency Inverter VFD022E21A

Our projects

Lithuanian

Lithuanian